Industries

Manufacturing operations are very specialised and differ from industry to industry. Each vertical has its own specific challenges, issues and requirements. Obviously, a digital transformation solution that promises to help industry to leverage digital must be tailored to specific requirements and challenges of the vertical.

PlantConnect SFactory takes into account this specific paradigm. The architecture allows industry specific modules to be plugged in seamlessly to provide unique experience, quick roll out and lower costs of ownership.

While designing these solutions we have leveraged experience and expertise of industry veterans to create industry specific solutions. Of course, each installation and client has offered additional insights on the requirements and helped to enrich the solution.

We have covered certain verticals more aggressively than others as listed below and additional verticals are under development and roll out.

Connect with us to know about solutions for your industry

Automotive Components – Metal/ Plastics

Indian automotive industry as a whole is growing very rapidly and is expected to continue the growth trajectory for many years to come. This growth will be further scaled with strong EV sector for 2, 3 and 4 wheelers.

Interestingly, auto companies very heavily depend on their supplier partners for all kinds of assemblies, sub-assemblies and components. In some cases, up to 90 % of components are outsourced. Auto majors are demanding that their partners deploy digital solutions and provide data driven visibility of the operations.

PlantConnect SFactory enables automotive components companies to comply with demands and requirements of their clients. Below are unique requirements of these companies. For full details of PlantConnect SFactory please access products page.

Automotive Components – Metal

- Connectivity with CNC machines and robots

- Operations improvement for robotic production lines and standalone machines

- Machine condition monitoring for CBM, especially for bottleneck machines

- Traceability of production data against product serial number

- Customizable digital inspection forms and records

- Machine vision based inspection solutions

Automotive Components – Plastics

- Handling of trial run

- Tracking of material wastage

- Monitoring of cycle time and other process parameters

- Mould life management

- Statistical Process Control (SPC) to catch and rectify process variabilities

PlantConnect SFactory Details

Electronics and White Goods

Indian Electronics and white goods sectors are witnessing double digit growth and sales are ramping up on just domestic demand. These are integrated facilities with component and critical assemblies being manufactured in house. There are also assembly lines where external supplied components including even PCBs are assembled, tested and readied for market.

Obviously, these companies depend very heavily on their supplier partners for all kinds of assemblies, sub-assemblies and components. In some cases, up to 90 % of components are outsourced. Quality, traceability and delivery schedules are some of the critical challenges in such scenarios.

PlantConnect SFactory enables both the OEMs and components companies to leverage digital capabilities. Additionally, compliance requirements like energy rating testing and validation, can also be serviced. Below are unique requirements of these companies. For full details of PlantConnect SFactory please access products page.

Components – Sheet Metal / Metal

- Connectivity with CNC machines and robots

- Stamping machines – cycle time and productivity

- Operations improvement for robotic production lines and standalone machines

- Machine condition monitoring for CBM, especially for bottleneck machines

- Traceability of production data against product serial number

- Customizable digital inspection forms and records

- Machine vision based inspection solutions

Components – Plastics

- Handling of trial run

- Tracking of material wastage

- Monitoring of cycle time and other process parameters

- Mould life management

- Statistical Process Control (SPC) to catch and rectify process variabilities

Components – Electronics

- Assembly line monitoring

- Testing lines monitoring and test results recording

- Machine vision based inspection and traceability

PlantConnect SFactory Details

Tool Rooms

Tool Rooms are a specialised vertical that is present in many companies and also offered as shared services by some companies. Tool room processes are very different from the typical line or continuous manufacturing processes. Key characteristics

- Single or small quantity of jobs

- Multiple operations

- Jobs typically take hours or days to complete

- Tracking of job progress is very important

PlantConnect SFactory offers a specialised module to cater for tool room requirements.

- Job scheduling with expected time for each operation

- Tracking of operations and alerts for delays

- Different method for OEE calculations

- Visibility in tool room operations

PlantConnect SFactory Details

Foundries

Indian foundry industry is coming of age and these companies are looking at domestic and global markets. Most of the foundries are now offering not just castings but also machined and finished products which are the real value-added business proposition.

The sector has very large and high-tech foundries producing top of the line products for defence and others and also small and medium size companies. Some areas have emerged as foundry clusters due to historical and business reasons.

PlantConnect SFactoryenables foundries to leverage digital in their operations and assist them in becoming a global class and competitive sector.

Foundry section

- Connectivity with furnaces, metal handling gantries, etc.

- Statistical Process Control (SPC) to catch and rectify process variabilities

- Energy monitoring and optimisation

- Heat and production monitoring

Machining section

- Connectivity with CNC machines and robots

- Traceability of production data against product serial number

- Customizable digital inspection forms and records

- Machine vision based inspection solutions

PlantConnect SFactory Details

Food & Beverages

Food and beverages sector is one of fastest growing sector in India with global, national and small players servicing their focus clients. Interestingly, whichever are the products and whatever the size of the company, client expectations on quality are same across the sector. This sector has stringent reporting and traceability requirements

With all these factors this sector has unique requirements and PlantConnect SFactory and PlantConnect Insights enable these companies to leverage digital in their operations and assist them in becoming a global class and competitive players.

Some of the sectors that we have covered in this domain are:

- Dairies and milk products plants

- Milk collection processes

- Fruit juice and pulp

- Bottling plants

- Packaged food

- Organic nutrients for plants

- Breweries

Below are unique requirements of these companies. For full details of PlantConnect SFactory and PlantConnect Insights please access products page.

Batch manufacturing

- Raw material intake – quantity and quality monitoring

- Batch process monitoring for Yield and OEE

- Process parameters monitoring

- Machine condition monitoring for CBM, especially for bottleneck machine

- Customizable digital inspection forms and records

Packaging and Supply Chain

- Connectivity to high-speed packaging machines

- Tracking of batches during packaging

- Monitoring of package weight variance

- Tracking of packages through supply chain

- Product genealogy solutions

Reporting (MIS)

F & B companies require an aggregated and brand agnostic historian and reporting solution.PlantConnect Insights is an ideal solution for these requirements. We have worked extensively with automation majors like Siemens, GEA, Tetrapack for providing these solutions.

- Connectivity with DCS from Siemens, ABB, Yokogawa and others

- Connectivity to various equipment such as weigh bridges, test equipment

- Customized manual forms

- Auto report generation and distribution

Process Industries

There is a huge variety in process industries. Various domains such as O&G, power, chemical, pharma and others have unique requirements. AIPL offers solutions for various aspects of a batch / continuous process industry.

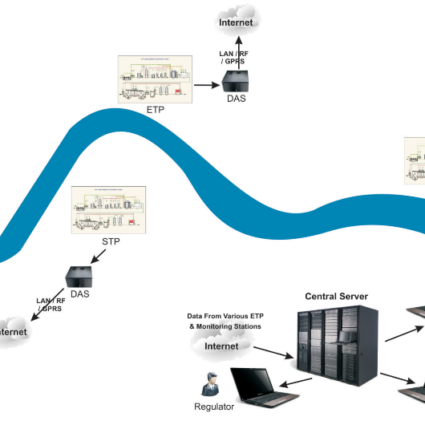

Emissions Monitoring

- Connectivity with all analyzer makes available in India

- Monitoring and regulatory reporting to CPCB / SPCB for

- CEMS

- ETP

- Ambient air

Reporting (MIS)

Process industries require an aggregated and brand agnostic reporting solution. PlantConnect Insights is an ideal solution for these requirements. We have worked extensively with automation majors like Siemens, GEA, Tetrapack for providing these solutions.

- Connectivity with DCS from Siemens, ABB, Yokogawa and others

- Connectivity to various equipment such as weigh bridges, test equipment

- Customized manual forms

- Auto report generation and distribution

PlantConnect Insights Details

Batch manufacturing

- Raw material intake – quantity and quality monitoring

- Batch process monitoring for Yield and OEE

- Process parameters monitoring

- Machine condition monitoring for CBM, especially for bottleneck machine

- Customizable digital inspection forms and records

PlantConnect SFactory Details

Packaging and Supply Chain

- Connectivity to high-speed packaging machines

- Tracking of batches during packaging

- Monitoring of package weight variance

- Tracking of packages through supply chain

- Product genealogy solutions

PlantConnect SFactory Details

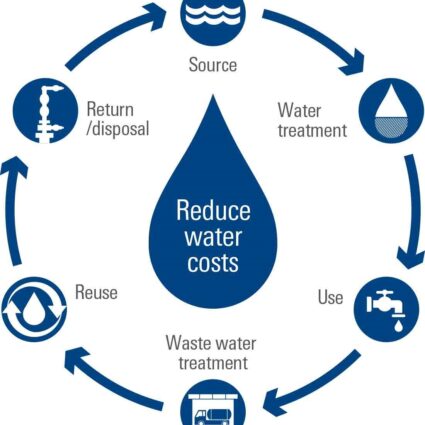

Water & Waste Water

At AIPL we are concerned with usage and misuse of water as a resource and we strive to provide digital solutions that will help all stake holders to get data and take informed decisions.

Ascent Intellimation offers PlantConnect as AIPL Water Platform for water vertical along with our ecosystem partners. AIPL’s main offering is an aggregator platform for data acquisition, data upload, analytics and dashboards, alerts and AI based tools for predictivity. Specific water use-cases we work with are:

- ETP / STP monitoring and data upload to pollution control boards

- Monitoring of water neutral industrial plants (ZLD)

- Ground water monitoring and reporting (CGWA)

- Pilferage and leakage monitoring and management

- Water grid monitoring and management for industrial and smart city projects

- Metered drinking water with Smart water meters along with quality monitoring

- River basin monitoring and management and Flood control

AIPL has built an ecosystem of partners who offer products and services that work in conjunction with AIPL Water Platform

- Water quality analyzers companies

- Flow meter manufacturers – piped and open channels

- Smart meter manufacturers

- ETP / STP contractors

- Water consultants

PlantConnect RAMS

Marine Assets

Marine assets (ships and other vessels) are distributed across the world and real time monitoring of these assets is critical for shipping companies. The platform must have robust and fault tolerant communication capabilities via satellites. PlantConnect SFactory offers these capabilities.

- Connectivity with ship assets such as engines, compressors

- Connectivity with bridge equipment

- Data acquisition of thousands of parameters and upload to cloud server

- Robust and fault tolerant communication through satellites

- Alarm and alerts module based on real time evaluation of conditions

- Data sharing with partners for advisory and other services